Professional Cold Heading Fasteners Solutions

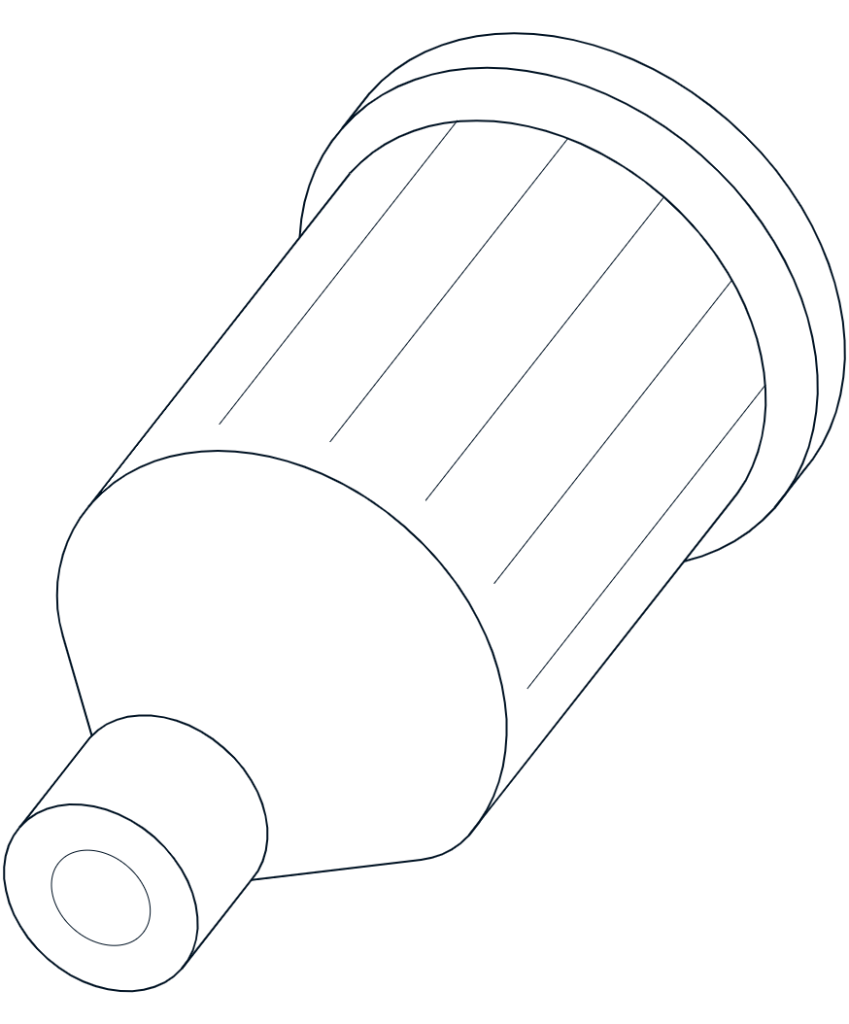

Cold Heading Fastener

Cold forging is a processing technology that changes shape by applying pressure at room temperature without heating metal.This method improves the internal structure of the metal and increases the strength and accuracy of the product. Cold forging is used in a wide range of fields, including the automobile industry, aerospace industry, and construction industry.Especially in the manufacturing of parts that require high strength and precision, it is an indispensable processing technology.

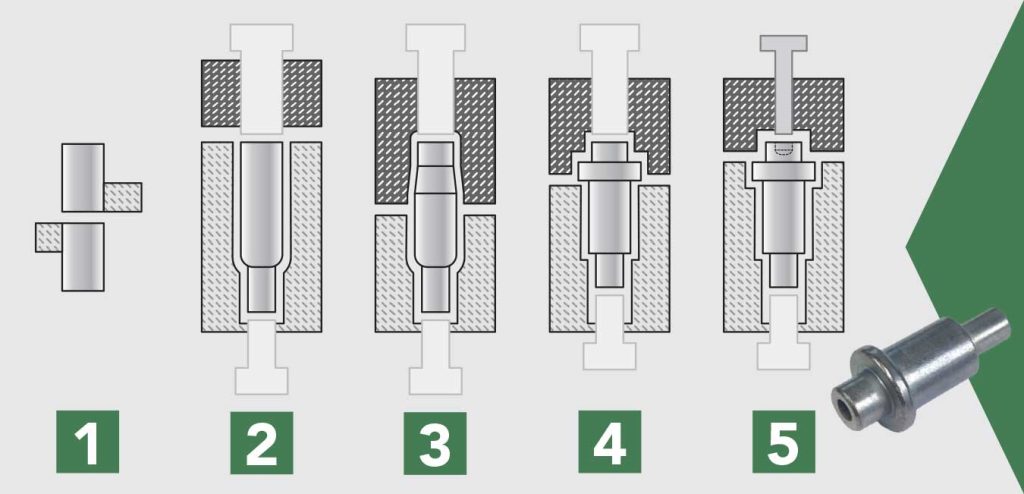

Here’s How the Cold Forming Manufacturing Process Works

- Blank is Cut from a coil of wire

- Advanced for Forming The blank is advanced into the first station

- Ist Form The blank is formed, then advanced to the next station

- 2nd Form During the same stroke of the machine, the previous part is formed again in the second station. Work is performed on multiple parts to produce one finished part per machine stroke. [Some parts require multiple dies and blows to form the intended design]

- Formed Part Completed part is ejected from die

Custom Cold Headed Parts, Fasteners, and Components Manufacturing.

As an industry leader of custom cold heading, we excel in manufacturing fasteners, parts, and components from 3/32” up to 1 1/4” in diameter and up to 9” in length. We are experts in producing a wide range of cold headed products quickly and cost-effectively, using virtually any material capable of being cold formed, including alloy steel, aluminum, brass, copper, medium and low carbon steels, nickel alloys, monel, silicon bronze, and stainless steels.

Micro Fasteners

Micro Cold Headed Pins

Miniature Valve Components

Miniature Medical Components

Why Use Cold heading?

Up to 70% Cost Savings

One of the biggest advantages of cold forming is cost savings. Cold forming is a net (or near-net) shape solution. During the process, wire is transformed by a sequence of die blows into a specific shape, with the material flowing to fill the part geometry and dimensional tolerances defined by the tooling. So there is virtually no waste created. Without scrap to deal with, there is little to no recycling cost associated with the process, less lubricant to reclaim, and minimal labor to handle it all. In general, the wire raw material is less expensive than the bar stock used for machining.

With all forms of screw machining, including single- and multi-spindle and Escomatic processes, scrap is not only unavoidable, it is a significant by-product of the process, often equivalent to 50% of the final part’s mass.

5X Faster Throughput Than Standard Machining

With an optimized part formation progression for a complex component, cold heading delivers yields at an average rate of 70-120 parts/minute (PPM) and can be up to 350 PPM in for some part designs. Generally, yields for a similar design produced from a multi-spindle screw machine will be in the 6 – 20 PPM range, an order of magnitude faster for cold forming. This faster yield ultimately reduces cost and speeds up product delivery for component and small metal part manufacturing.

Consistent,Reliable Quality at High Tolerances

Not only does cold forming allow for parts to be manufactured quickly, but also accurately and consistently. Critical and close tolerances can still be achieved in high volumes over time versus more expensive machining processes. Additionally, these tolerances are maintained consistently throughout the production process making sure that every piece follows the project’s design spec from start to finish.

Increased Tensile Strength

Cold forming is a process in which the native tensile strength of the material is increased through work hardening. Here’s how it works: For every 1% of area reduction or increased surface area of a part’s cross-section due to cold forming, its tensile strength increases by a factor of ~0.6-1.5 depending on the alloy. This physical property is known as the work hardening rate of the material. The work hardening rate varies depending on starting tensile strength and material composition.

No process that removes material from the native shape, such as screw machining, can achieve this.

Environmentally Friendly

Because cold forming produces virtually no metal scrap, it requires less reprocessing, along with its associated costs of transportation, fuel, and labor. Lubricant is used in the die formation process but at a fraction of the rate for a screw machine (cutting) operation.

For screw machine operation, materials often contain free machining additives. These free machining additives are added directly to the molten metal before casting into ingots. They are not soluble in the alloy composition and form discrete particles of various shapes and sizes in the ingot casting.

Cold forming does not require these additives. From an engineering perspective, because the raw material has fewer inclusions, a cold-formed part lends itself to a superior potential design.