Industrial fasteners used in wind power generation

Wind power generation places extremely high demands on bolt connections, characterized by high strength and high precision. Wind power fasteners need to withstand various alternating loads. In addition to axial preloads, they must also endure alternating tensile loads, transverse shear alternating loads, and more. The operating environment is harsh, with long-term exposure to extreme temperatures ranging from -40°C to 100°C. Wind farms in certain areas, especially offshore wind farms, also face challenges from high humidity and high salinity corrosion. We have taken necessary measures in areas such as raw material selection, structural design, manufacturing processes, production management, testing, and on-site assembly to ensure the reliability of bolt connections in wind power generation. As experts in the field of wind energy fasteners, JF has extensive experience in the manufacturing and supply of wind power fasteners, including tower bolts, nacelle bolts, blade studs, and other wind power fasteners.

Pre-stressed anchor bolt for wind power foundation

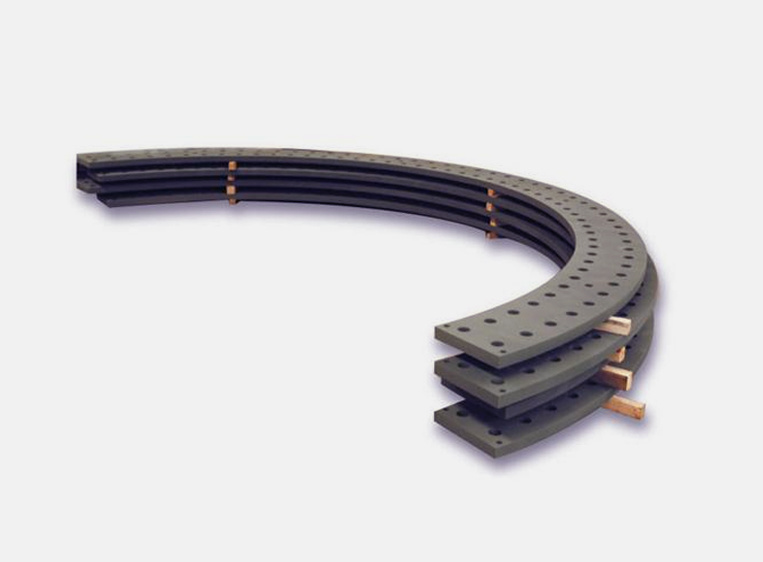

Wind Turbine Anchor Bolt Cage

Wind turbine tower bolts

Flanged connection bolt, grade 10.9

Wind turbine tower bolts

Blade bolt (double-ended bolt)

blade bolt

Anchor Plate Q355NE

Product Description

Product processing technology features:

(1) The characteristics of our company’s anchor bolt production process: the anchor bolt is heat treated before rolling the thread; After the whole anchor bolt has passed the heat treatment and inspection, the whole anchor bolt will be peeled and finely ground to the specified medium diameter size. The grinding process can remove the oxide scale and decarburized layer generated during the heat treatment process. Then the thread is rolled into thread.

(2) The raw material of anchor bolt is 42CrMoA and other materials, which are purchased from large domestic steel mills. Before leaving the factory, the raw materials shall be tested by 100 ultrasonic flaw detection, and shall be qualified for Grade A according to GB/T 4162 standard. The performances of anchor bolts shall meet the requirements of the technical specifications of the bidding documents.

(3) The middle rod of the anchor bolt is not machined to ensure one-time forming and better thread accuracy.

anchor bolt processing process:

According to the plan, purchase raw materials (materials and grades of designated steel mills) → re-inspection of raw materials → rough straightening → heat treatment (intermediate frequency induction heat treatment) → inspection (performance inspection) → peeling and fine straightening (100% ultrasonic flaw detection, fluorescent magnetic particle flaw detection, etc.) → blanking → machining (chamfering) → coding → thread rolling → inspection (thread accuracy gauge, medium diameter micrometer, etc.) → anchor bolt tension detection → anchor bolt anti-corrosion treatment (dacrome, grease + heat shrinkable tube, etc.) → inspection → packaging → warehousing according to customer requirements.

Detailed process flow of anchor bolt:

(1) Re-inspection of raw materials: according to the requirements of the signed technical documents.

(2) Rough straightening: In order to ensure uniform temperature and cooling in the quenching and tempering process, so as to ensure uniform hardness, uniform mechanical properties and small deformation of each part of the long bar, straightening must be carried out before heat treatment quenching and tempering to ensure straightness, and a special straightening machine is used for straightening.

(3) Heat treatment: Quenching and tempering process is adopted, I .e. quenching and high temperature tempering, to meet the mechanical properties of 8.8 and 10.9 grade anchor bolts (according to the requirements of the bidding technical documents).

(4) Performance test: according to the requirements of technical specifications.

(5) peeling: surface peeling, removing surface defects, oxide skin, etc.

(6) Grinding middle diameter: finish grinding to the middle diameter to ensure that the straightness and surface roughness meet the drawing requirements.

(7) Ultrasonic + eddy current flaw detection: 100 ultrasonic flaw detection, in line with Class A standard, 100 eddy current sorting to ensure no mixing.

(8) Magnetic particle flaw detection: 100% magnetic particle flaw detection shall be carried out according to the requirements of the bidding technical documents to prevent products with surface cracks or material surface defects from flowing into the next process.

(9) blanking: use sawing machine blanking to remove the excess parts at both ends.

(10) Chamfering: Special chamfering equipment is used, and both ends are chamfered according to the requirements of the drawings.

(11) Coding: use a coding machine to code each anchor bolt according to the requirements of the drawings to determine the traceability of the product.

(12) Thread rolling: use thread rolling machine to make thread, and use thread micrometer and stop gauge to detect the thread of anchor bolt to ensure that the thread size and accuracy meet the technical requirements.

(13) Anchor bolt tension test: according to the requirements of the bidding technical documents.

(14) Anchor bolt anti-corrosion treatment: Anchor bolt anti-corrosion treatment shall be carried out according to the requirements of the bidding technical documents.

(15) Packing: check the products before packing, and design special tooling suitable for the transportation of anchor bolts of specific length to prevent the products from bending and other damages during transportation.

anchor plate processing process:

According to the plan, purchase steel plate (Q345E)→ re-inspection of raw materials → blanking (numerical control programming, flame cutting) → leveling → inspection → groove opening → cleaning and grinding → anchor plate assembly pair welding → inspection (100 ultrasonic flaw detection) → cleaning and grinding → appearance inspection → leveling → flatness detection → machining → inspection → numerical control drilling → inspection → sandblasting → anti-corrosion treatment → inspection → packaging → warehousing.